máy đầu cuối uốn tước

Đạt được quá trình xử lý dây liền mạch với máy uốn tuốt dây có độ chính xác cao

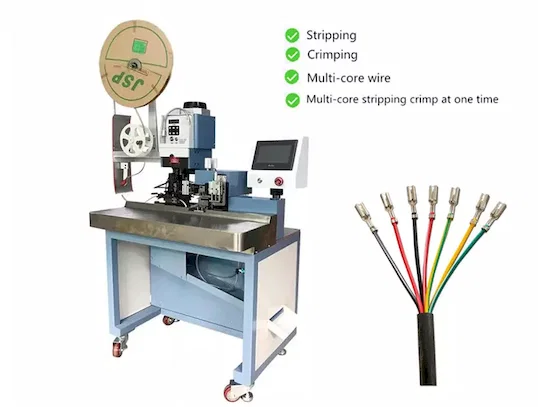

Giới thiệu Máy uốn tuốt dây, một giải pháp hiệu quả cao và chính xác cho nhu cầu xử lý dây của bạn. Máy đầu cuối tuốt và uốn tiên tiến này, cụ thể là Máy đầu cuối tuốt và uốn dây cấp liệu cuối (Model: WPM-2008A2-E), hợp lý hóa việc chuẩn bị dây bằng cách tích hợp tuốt và uốn vào một hoạt động duy nhất, mạch lạc. Tối đa hóa công suất sản xuất của bạn, nâng cao độ chính xác và giảm thiểu tiếng ồn với thiết bị tiên tiến này.

Integrated Operations for Unmatched Efficiency and Precision

The End-feed Wire Stripping and Crimping Terminal Machine WPM-2008A2-E is engineered for seamless wire processing. Its innovative design combines wire stripping and terminal crimping within a one-time cassette mold holder and skinning system. This integrated approach ensures a coherent motion throughout the machine's operation, resulting in faster cycle times and reduced material handling.

Unwavering Accuracy and Stability

Precision is paramount in wire processing, and the WPM-2008A2-E excels in this area. Built with the assembly of high-precision parts and featuring a meticulous adjustment method using tuning screws, this machine delivers exceptional accuracy. Experience crimping and stripping precision down to 0.05 - 0.1 mm, ensuring consistent and reliable wire terminations every time.

Quiet, Energy-Saving, and Reliable Performance

Operate in a comfortable and efficient workspace. This Wire Stripping Crimping Machine is equipped with Japanese SMC pneumatic components, known for their energy conservation and remarkably noise-free operation. The electrical system further emphasizes efficiency and reliability by adopting high-quality components that are both energy-saving and stable, contributing to long-term, dependable performance.

Key Features and Benefits of the Wire Stripping Crimping Machine WPM-2008A2-E:

-

Integrated Stripping and Crimping: Combines operations for increased efficiency and reduced cycle times.

-

One-Time Cassette Mold Holder: Ensures coherent and streamlined machine motion.

-

High-Precision Construction: Assembled with high-precision parts for exceptional accuracy.

-

Tuning Screw Adjustment: Enables meticulous precision adjustments.

-

Japanese SMC Pneumatic Components: Energy-saving and noise-free operation for a comfortable workspace.

-

Energy-Saving Electrical System: High-quality, stable, and energy-efficient electrical components.

-

End-Feed Design: Facilitates efficient wire feeding.

-

Wide Wire Capacity: Handles wire sizes from AWG#18 to 36#.

-

High Production Capacity: Achieves a production capacity of 3000 - 3500 pieces per hour.

-

Adjustable Stripping Length: Stripping length adjustable from 1.0 to 10.0 mm.

Technical Specifications: End-feed Wire Stripping and Crimping Terminal Machine (WPM-2008A2-E)

PRODUCTION CAPACITY 3000-3500pcs/h

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek